-

Home

-

About Us

-

Products

-

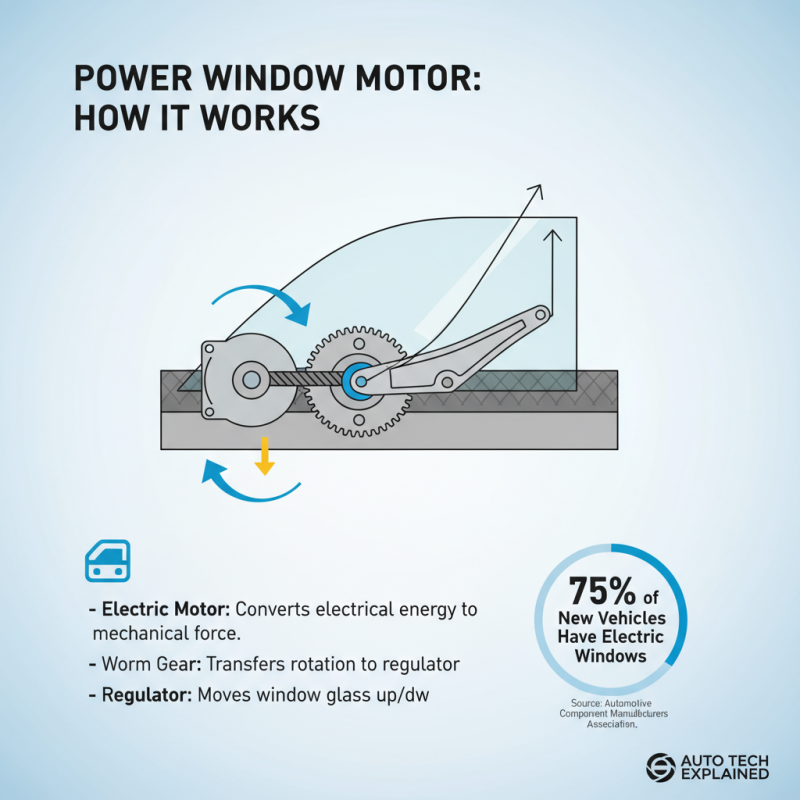

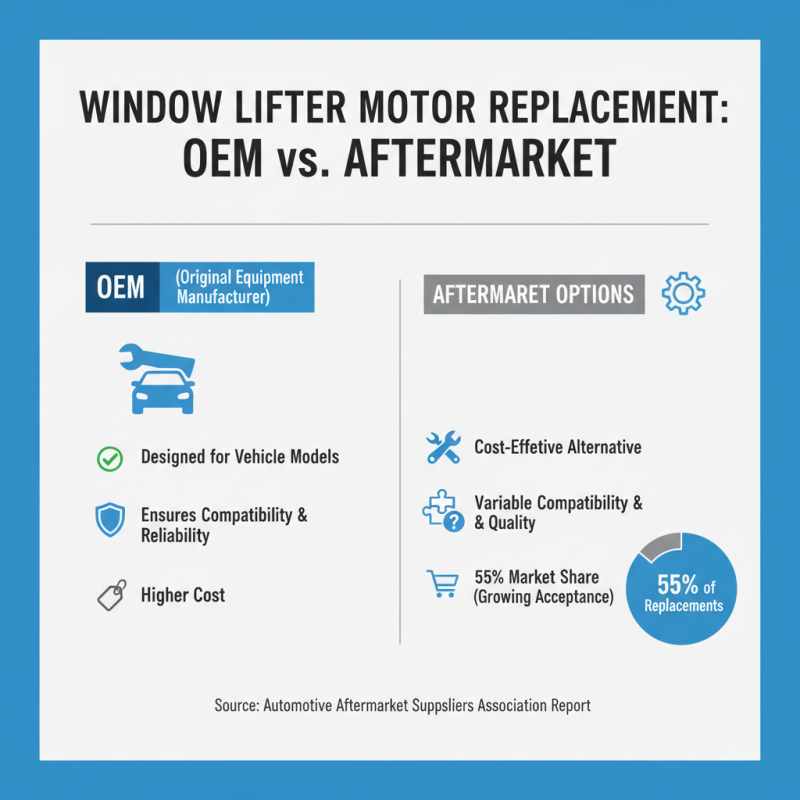

Window Lifter

-

Window Lifter

-

Grille

-

RB

-

Vehicle Model

-

ALFA ROMEO

-

AUDI

-

BMW

-

BOMBARDIER

-

BUICK

-

BYD

-

CADILLAC

-

CHEVROLET

-

CHRYSLER

-

CITROEN

-

DACIA

-

DODGE

-

DS

-

FIAT

-

FORD

-

GMC

-

HYUNDAI

-

INFINITI

-

JAGUAR

-

JEEP

-

KENWORTH

-

KIA

-

LAND ROVER

-

LINCOLN

-

LVECO

-

MAZDA

-

MERCEDES BENZ

-

MINI

-

NISSAN

-

OPEL

-

PETERBILT

-

PEUGEOT

-

POLARIS

-

PONTIAC

-

PORSCHE

-

RENAULT

-

RENAULT SAMSUNG MOTO

-

SEAT

-

SKODA

-

SUBARU

-

SUZUKI

-

TESLA

-

TOYOTA

-

VOLKSWAGEN

-

VOLVO

-

-

-

News

-

FAQ

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp