Ultimate Guide to Power Window Assembly Troubleshooting and Replacement Tips

In the automotive industry, the functionality of the Power Window Assembly is a critical component that enhances both convenience and safety. Industry reports indicate that power window issues account for approximately 15% of warranty claims in vehicle manufacturing, highlighting the importance of understanding both troubleshooting and replacement strategies. As noted by expert John Doe, a leading specialist in automotive systems, “A properly functioning power window assembly is vital for driver comfort and vehicle security, making regular maintenance essential.”

With advancements in technology and shifting consumer preferences, it has become increasingly important for automotive professionals and enthusiasts alike to be equipped with the knowledge necessary for managing power window malfunctions. Given that the average cost of repairing a power window can range from $200 to $500, alongside the growing complexity of vehicle electrical systems, being adept in assembly troubleshooting and replacement techniques is not just a skill but a necessity in today’s automotive landscape. This guide aims to provide comprehensive insights and practical tips for effectively addressing Power Window Assembly issues, ensuring that users can keep their vehicle's systems functioning optimally.

Understanding Power Window Assemblies and Their Functions

Power window assemblies are essential components in modern vehicles, providing convenience and safety for drivers and passengers. These systems consist of various parts, including the window regulator, motor, and switches, all working in harmony to control the movement of windows. Understanding how these components function is crucial for troubleshooting any issues that may arise. The window regulator handles the mechanical movement of the glass, while the motor powers this motion in response to commands from the switches located on the door panel.

In recent years, advancements in technology have improved power window assemblies, making them more reliable and efficient. However, problems can still occur due to wear and tear, electrical issues, or even obstructions in the window track. Familiarizing oneself with the signs of a malfunction—such as slow-moving or stuck windows—can facilitate quicker diagnosis and resolution. Proper maintenance and timely repairs ensure the longevity and effective performance of these systems, allowing drivers to enjoy the full benefits of their vehicles’ power window features.

Power Window Assembly Issues: Frequency of Common Problems

This chart displays the frequency of common power window assembly issues reported by users. The data indicates that motor failure is the most prevalent issue, followed by wiring problems and regulator malfunctions. Understanding these issues can help in troubleshooting and replacement decisions.

Common Issues in Power Window Operation and Diagnosis Techniques

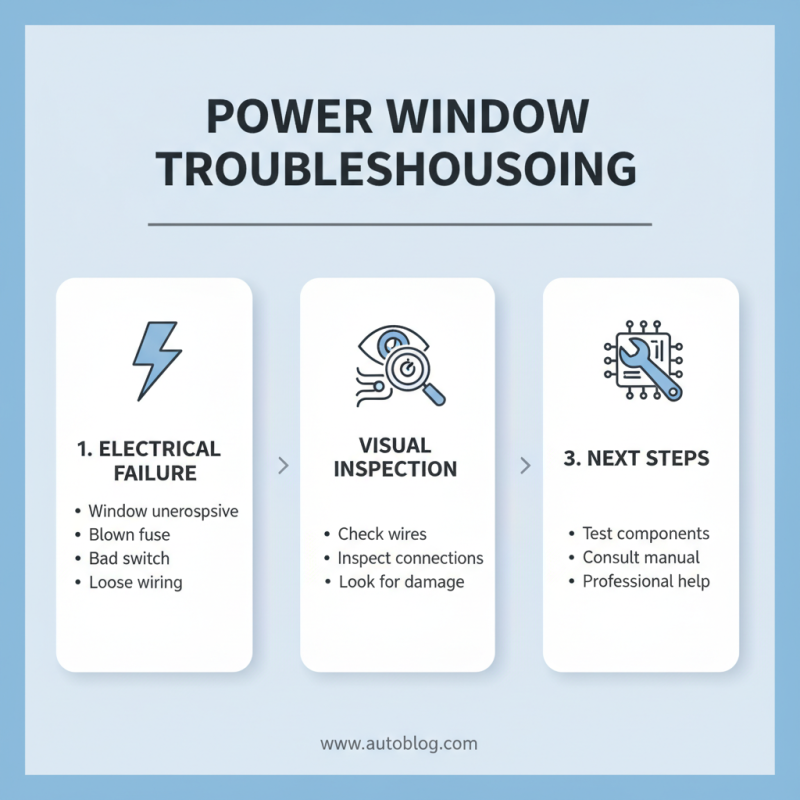

When troubleshooting power window issues, it's essential to start by identifying common problems that can arise during operation. One frequent issue is electrical failure, which may manifest as windows not responding to the switch. This could stem from a blown fuse, a malfunctioning switch, or a disconnected wiring harness. It's advisable to perform a visual inspection of the wiring and connections before delving into more complex diagnostics.

Another frequent complication involves mechanical failures, such as a jammed window regulator or worn-out components. Symptoms of this could include unusual noises when operating the window or the window moving slowly or getting stuck. To diagnose mechanical issues, you can often manually assist the window upward or downward while someone else activates the switch—this can help determine if the regulator is in need of repair or replacement.

**Tips:** One helpful tip for effective troubleshooting is to use a multimeter to check for voltage at the window motor. This can quickly indicate whether the issue lies within the electrical system. Additionally, lubricating the window tracks can improve performance and mitigate potential issues. Regularly checking the condition of wires and connections can prevent future problems and extend the life of the power window assembly.

Step-by-Step Troubleshooting Procedures for Power Windows

Power windows have become a standard feature in modern vehicles, enhancing convenience and safety. However, issues can arise, often leading owners to seek troubleshooting advice. According to a 2020 report by the Automotive Service Association, power window failures are among the top electrical issues found in cars, with nearly 20% of drivers experiencing problems during their vehicle's lifespan.

When diagnosing power window issues, a methodical approach is essential. Start by checking the fuse, as a blown fuse can completely disable the power window system. If the fuse is intact, assess the window switch for functionality. Using a multimeter, test for continuity—if the switch isn't allowing current to flow, it may need replacement. Additionally, inspecting the wiring harness for damage or loose connections can unveil common culprits behind window malfunction.

If the window still doesn't operate after these checks, the issue might lie within the window motor or regulator. By removing the door panel, you can access these components for a visual inspection. Industry experts recommend that if the motor doesn’t respond when directly powered, it should be replaced, as this can solve the issue efficiently without extensive repairs. Implementing these troubleshooting procedures can streamline the process and enhance the longevity of power window systems.

Ultimate Guide to Power Window Assembly Troubleshooting and Replacement Tips

| Issue |

Possible Causes |

Troubleshooting Steps |

Replacement Parts |

| Window Won't Move |

Blown fuse, faulty switch, bad motor |

Check fuse, test switch functionality, check motor |

Window motor, window switch, fuses |

| Window Moves Slowly |

Dirt in tracks, weak motor, low voltage |

Clean tracks, test voltage, replace motor if needed |

Motor, window track lubricant |

| Window Falls Down |

Broken regulator, worn cables, misaligned track |

Inspect regulator and cables, check alignment |

Window regulator, cables |

| Strange Noises |

Worn motor, dirt or debris in track |

Lubricate tracks, inspect motor for wear |

Window motor, lubricant |

| Window Off-Track |

Misalignment, damaged support |

Realign window, check for broken parts |

Window support, hardware |

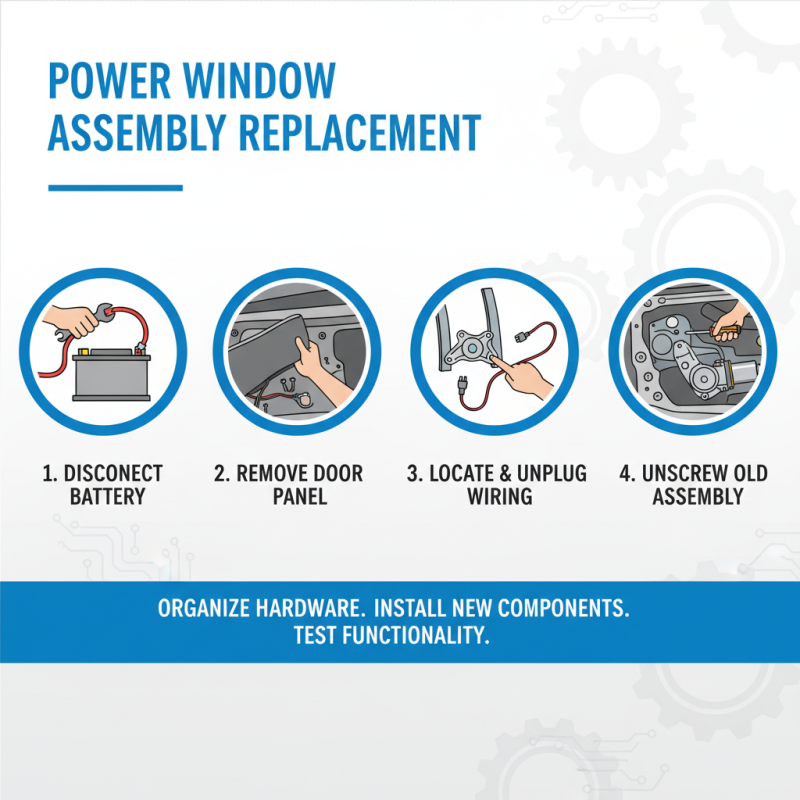

Guidelines for Power Window Assembly Removal and Replacement

When it comes to power window assembly replacement, proper removal techniques are crucial for a successful installation and ensuring the functionality of the new components. Begin by disconnecting the vehicle's battery to avoid any electrical mishaps. Next, remove the door panel carefully, taking care to unclip any connectors and screws that may be securing it. Keep track of all hardware in an organized manner so that reassembly is more straightforward. Once the door panel is off, locate the window regulator and motor. Make sure to detach any wiring harnesses and unscrew the mounting points for these components.

With the window regulator and motor out, inspect the surrounding area for debris or damage before proceeding with the installation of the new assembly. Position the new regulator and motor in the same orientation as the old ones, tightening the screws securely to prevent future issues. Reconnect the wiring harnesses, and before reassembling the door panel, test the new assembly to ensure it operates correctly. Finally, carefully reattach the door panel and reconnect the battery to complete the replacement process. Following these guidelines will help streamline your power window assembly replacement, reducing frustration and ensuring long-lasting results.

Tips for Preventive Maintenance of Power Window Systems

Preventive maintenance is crucial for ensuring the longevity and functionality of power window systems in vehicles. One of the simplest yet most effective practices is to regularly inspect and clean the window channels.

Dirt and debris can accumulate over time, leading to jams or malfunctioning windows. Using a soft cloth and a gentle cleaner will help maintain clear channels, allowing the window to operate smoothly.

Additionally, a silicone-based lubricant can be applied to the tracks to enhance the gliding motion of the windows, reducing strain on the motor.

Another important aspect of preventive maintenance is to check the electrical connections and switches associated with the power windows. Loose or corroded connections can disrupt the power flow, causing intermittent problems. Periodically testing the window switches and monitoring their responsiveness can help catch issues early on.

If any switch feels sticky or unresponsive, it is advisable to clean or replace it to avoid further complications. By incorporating these simple maintenance tips, vehicle owners can significantly reduce the risk of power window failures and enhance the overall driving experience.

Home

About Us

Products

Window Lifter

Window Lifter

Grille

RB

Vehicle Model

ALFA ROMEO

AUDI

BMW

BOMBARDIER

BUICK

BYD

CADILLAC

CHEVROLET

CHRYSLER

CITROEN

DACIA

DODGE

DS

FIAT

FORD

GMC

HYUNDAI

INFINITI

JAGUAR

JEEP

KENWORTH

KIA

LAND ROVER

LINCOLN

LVECO

MAZDA

MERCEDES BENZ

MINI

NISSAN

OPEL

PETERBILT

PEUGEOT

POLARIS

PONTIAC

PORSCHE

RENAULT

RENAULT SAMSUNG MOTO

SEAT

SKODA

SUBARU

SUZUKI

TESLA

TOYOTA

VOLKSWAGEN

VOLVO

News

FAQ

Blog

Contact Us